Φ26×12 Max. Perçage CNC Angle métal Perçage Marquage et ligne de cisaillement 3 axes CNC

Industrie concernée:

Cette machine est un dispositif spécialisé spécialement conçu pour effectuer des opérations de poinçonnage, de marquage et de cisaillement d'acier d'angle.Il est spécialement conçu pour répondre aux besoins de traitement de base de l'industrie des tours en acier angulaire, assurant une manipulation précise et efficace des composants en acier d'angle essentiels à la fabrication de tours.

Les spécifications:

| Les fonctions |

Parures, marquages et coupes |

| Taille de l'angle ((mm) |

¥40×40×3 ¥140×140×12 |

| Longueur maximale de l'espace vide (m) |

12 |

| Longueur maximale du produit fini (m) |

10 |

| Max. perçage (diamètre х épaisseur) (mm) |

Le système de détection doit être équipé d'un dispositif de détection de la pollution atmosphérique. |

| Points par côté |

2 |

| Force de frappe (kN) |

630 |

| Force de marquage (kN) |

630 |

|

Force de coupe (kN)

|

1800 |

| Groupe de lettres de marquage |

4 |

| Nombre de lettres par groupe |

12 |

| Dimension de la lettre (mm) |

14 × 10 × 19 |

| Mode de coupe |

Coupe à lame unique |

| Machines à coudre |

3 |

| Vitesse d'alimentation de l'angle (m/min) |

80 |

| Méthode de refroidissement du système hydraulique |

Refroidissement par eau |

| Précision de traitement |

Conformité à la norme GB2694 |

| Fonction du programme |

Entrée par clavier et interface USB |

| Dimension (en mm) |

28000 × 6500 × 2200 |

Composition du produit:

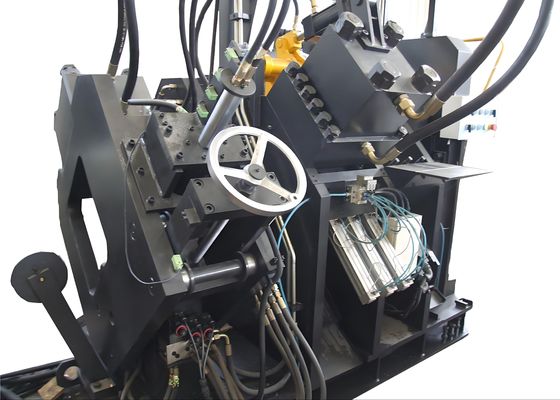

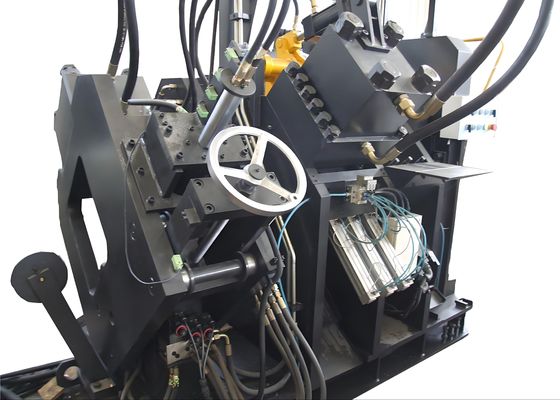

Cet équipement est principalement composé d'un convoyeur transversal, d'un système de chargement rotatif, d'un convoyeur d'alimentation, d'un chariot d'alimentation CNC, d'un module de perforation, d'un module de marquage, d'un module de coupe,et un convoyeur de déchargement ainsi qu'un convoyeur hydraulique, systèmes électriques et pneumatiques, entre autres composants.

Caractéristiques du produit:

1Il utilise la technologie CNC et l'alimentation servomotrice, offrant une efficacité opérationnelle élevée et une précision constante de la pièce.les composants électriques sont d'origine importée.

2Chaque côté est équipé de trois ensembles de poinçons et de matrices, qui peuvent accueillir trois types de poinçons de diamètres différents.les trois ensembles de moules peuvent se déplacer de manière synchrone pour régler la marque de référence de perforation.

3. L'ordinateur dispose d'une interface chinoise/anglaise, permettant un fonctionnement convivial, et prend en charge l'affichage des dessins de la pièce.et l'équipement peut directement utiliser les données de programme générées par le logiciel de loftingLors de l'édition d'un programme, seule la taille de la pièce, le diamètre du trou, la marque de référence et la quantité de la pièce doivent être entrées.

4Le véhicule d'alimentation CNC est entraîné par un servomoteur, avec un codeur photoélectrique fournissant des informations de rétroaction.

5Les processus de marquage, de poinçonnage et de cisaillement sont entièrement automatisés. Tous les composants d'acier d'angle finis peuvent être déchargés via un dispositif de renversement pneumatique, réduisant ainsi l'intensité du travail.

6Le système de commande est composé d'un ordinateur hôte, d'un système CNC, d'un servo moteur, d'un PLC et de capteurs de détection externes, entre autres composants.Les opérations de traitement sont initiées simplement en saisissant les dimensions de la pièce à usinerEn outre, les programmes peuvent être stockés, sélectionnés, affichés et transmis en fonction des numéros de pièce.

7L'unité de marquage adopte une structure en cadre fermé, assurant une excellente rigidité.La marque de référence de marquage peut être réglée arbitrairementLes cylindres pour le poinçonnage, le marquage et le cisaillement ont des spécifications plus grandes; le chariot NC est un modèle amélioré et plus robuste; et les pinces présentent une résistance structurelle améliorée.

Ces échantillons, qui couvrent les spécifications et les scénarios de traitement communs dans l'industrie des tours en acier angulaire, permettent aux utilisateurs d'inspecter directement la qualité de traitement, la précision, la précision et la précision des équipements.et de l'artisanatIls constituent une référence tangible pour évaluer les performances de l'équipement et sa compatibilité avec les exigences spécifiques de la production.

In the construction of ultra-high voltage (UHV) transmission lines—where towers are required to withstand extreme meteorological conditions and heavy loads—this equipment plays a crucial role in processing the angle steel components that form the main framework of the towersIl effectue avec compétence les opérations de forage et d'emboutissage pour l'acier d'angle utilisé dans les corps de tours, les bras croisés et autres composants structurels clés,assurer des dimensions précises et des connexions robustes pour garantir la stabilité globale des tours.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!