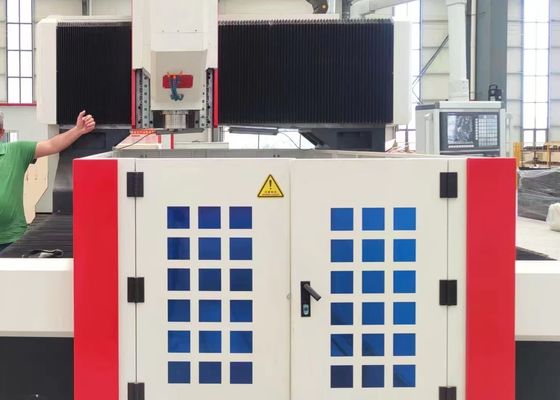

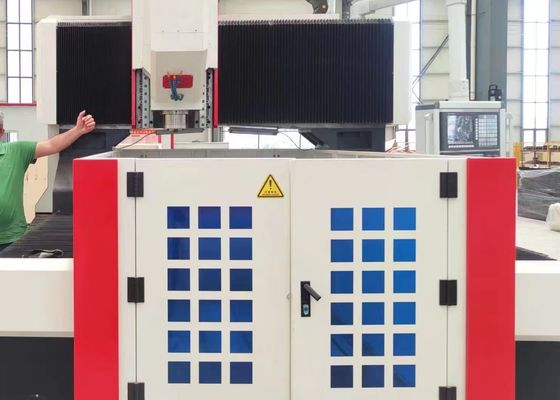

Dimensions hors tout 4000x3800x2800mm Machine de perçage CNC mobile avec table de travail Diamètre de perçage max. 60mm

Application:

La perceuse-fraiseuse CNC de type portique est principalement conçue pour effectuer des opérations de perçage, de chanfreinage, de taraudage et de fraisage sur des pièces en plaque et des composants structurels. Son champ d'application comprend des pièces telles que les brides, les disques, les anneaux et les plaques plates, avec des spécifications d'épaisseur strictement conformes aux paramètres de traitement efficaces définis de l'équipement. La machine facilite l'usinage de trous traversants et de trous borgnes sur des pièces en matériau unique et des composants en matériau composite. Dotée d'un contrôle numérique tout au long du flux de travail d'usinage, elle offre une facilité d'utilisation et une efficacité supérieures. Elle est bien équipée pour prendre en charge la production automatisée, obtenir des résultats d'usinage de haute précision et répondre aux exigences des scénarios de fabrication multi-variétés et à grande échelle.

Spécifications :

| Taille de la pièce |

Lxl |

1200x1200 mm |

| Hauteur du portique |

750 mm |

| Établi |

Largeur des rainures en T |

18mm |

| Tête de puissance de perçage |

Qté. |

1 |

| Cône de broche |

BT50 |

|

Diamètre de perçage max.

(Acier au carbone ordinaire)

|

Φ60 mm |

| Diamètre de taraudage |

M3-M28 |

| Vitesse de broche |

30~3000 tr/min |

| Puissance du moteur de broche servo |

22kW |

| Distance de l'extrémité inférieure de la broche à la table de travail |

200-750mm |

|

Mouvement latéral de la tête de puissance(Axe X)

|

Course horizontale max. |

1200 mm |

| Vitesse de déplacement latéral |

0~8 tr/min |

| Puissance du servomoteur pour le mouvement latéral |

2.4kW |

| Mouvement longitudinal du portique (axe Y) |

Course d'avance max. |

1200 mm |

| Vitesse d'avance |

0~8 m/min |

| Puissance du servomoteur d'avance |

2.4kW |

| Mouvement d'avance vertical du bélier (axe Z) |

Course max. |

550 mm |

| Vitesse de déplacement |

0~8 m/min |

| Puissance du servomoteur |

2.8kW (Frein) |

| Précision de positionnement sur trois axes |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Précision de positionnement répétée sur trois axes |

X/Y/Z/A/B/C |

±0.01/1000mm |

| Dimensions hors tout |

LxlxH |

4000x3800x2800 mm |

Caractéristiques du produit

1. Système de transmission :

Les rails de guidage et les curseurs de haute précision provenant de Taïwan sont conçus pour garantir des performances opérationnelles fluides tout en améliorant considérablement la capacité de charge lourde de l'équipement.

L'axe X et l'axe Z sont configurés avec respectivement deux et quatre guides linéaires à rouleaux, servant de mécanismes de guidage et de support de charge pour le mouvement latéral et longitudinal. Cette configuration répond pleinement aux exigences techniques des opérations de perçage à grande vitesse. Pour la transmission de puissance, l'axe X et L'axe Z adoptent des servomoteurs CA pour entraîner des vis à billes de précision, convertissant le mouvement rotatif en un déplacement linéaire précis.

L'axe Y est équipé de deux guides linéaires à rouleaux robustes, chacun équipé de deux curseurs à rail carré pour former le mécanisme de glissement de l'axe Y. Cette conception structurelle répond non seulement aux exigences de rigidité et de résistance élevées du bâti du portique, mais offre également des avantages techniques, notamment un faible coefficient de frottement, une vitesse de déplacement élevée, d'excellentes performances d'amortissement des vibrations et une durée de vie prolongée. Pour la transmission de puissance, l'axe Y adopte la technologie d'entraînement synchrone par servomoteur, qui entraîne de manière synchrone les vis à billes pour qu'elles tournent, actionnant ainsi le mouvement alternatif de l'établi de l'axe Y pour réaliser des opérations d'usinage CNC précises.

2. Système de lubrification automatique et mécanismes de protection :

Cette machine-outil est équipée d'un système de lubrification automatique à pression partielle volumétrique fabriqué à Taïwan. Il assure une lubrification automatique complète et sans angle mort des composants mobiles tels que les rails de guidage, les vis mères et les crémaillères, protégeant efficacement la durée de vie de la machine-outil. L'axe X et l'axe Y de l'équipement sont équipés de capots de protection anti-poussière, tandis que des protections anti-éclaboussures étanches sont installées autour de l'établi pour améliorer la protection opérationnelle.

3. Système central de distribution de liquide de refroidissement :

Cette machine-outil est livrée en standard avec un système central de distribution de liquide de refroidissement. Le système de circulation interne du liquide de refroidissement empêche efficacement les copeaux de fer d'adhérer à l'outil pendant les opérations d'usinage, réduit l'usure de l'outil, prolonge la durée de vie de l'outil et améliore l'état de surface des pièces. La sortie de liquide de refroidissement haute pression au niveau de la pointe de l'outil offre une protection fiable à la fois à la surface de la pièce et au joint rotatif à grande vitesse, empêche le colmatage du joint rotatif induit par les impuretés et contribue à l'amélioration globale de la qualité de la pièce et de l'efficacité opérationnelle.

Cet équipement industriel CNC de type portique haute performance, dédié aux applications de perçage et de marquage de tôles et de tôles, est méticuleusement conçu pour l'usinage de précision de composants de type plaque et de pièces structurelles. Spécifiquement optimisé pour le traitement de pièces telles que les brides, les disques, les anneaux et les plaques plates, il intègre une spécification de base selon laquelle l'épaisseur de ces pièces doit strictement respecter les paramètres d'usinage efficaces préconfigurés de la machine.

Dans les installations de fabrication de structures en acier, cet équipement effectue des opérations de perçage et de fraisage de précision sur des plaques structurelles et des éléments de connexion, jetant ainsi une base solide pour l'assemblage stable des ossatures en acier. Dans l'industrie de l'énergie éolienne, il fournit des solutions d'usinage de haute précision pour les tours et les brides d'éoliennes, un processus essentiel qui garantit que ces composants sont capables de résister à des conditions environnementales sévères (par exemple, vents intenses, variations de température). Pour les projets de construction de ponts, l'équipement traite les poutres de pont et les supports, facilitant la formation de connexions stables et durables conçues pour résister aux charges dynamiques tout au long de la durée de vie prolongée du pont.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!