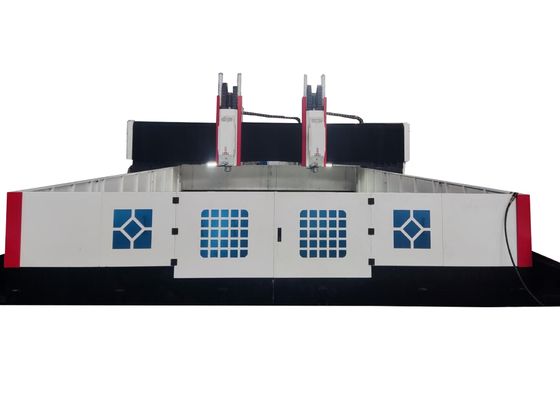

6000x3900x2700mm Taille globale Machine de perçage CNC à grille métallique 70mm Diamètre maximal de perçage

Application du projet:

Cet équipement est spécialement conçu pour les opérations de forage, d'écaillage, de fraisage et de fraisage sur plaques et composants structurels.Il est principalement conçu pour le forage à haut rendement de pièces de travail, y compris les brides., disques, anneaux et plaques dont l'épaisseur correspond à la plage de traitement efficace spécifiée.Le système facilite l'usinage des trous et des trous morts sur les composants mono-matériels et les matériaux compositesAvec un contrôle numérique de ses processus d'usinage, la machine-outil offre une commodité opérationnelle supérieure, répondant aux exigences de la production automatisée, de la fabrication de haute précision,transformation à plusieurs variétés, et des scénarios de production à grande échelle.

Les spécifications:

| Taille de la pièce |

LxW |

Pour les appareils à commande numérique |

| Hauteur du gantry |

800 mm |

| bureau de travail |

Largeur de la fente en T |

28 mm |

| Tête de puissance de forage |

Je suis désolée. |

1 |

| Tone de la broche |

NT1 société civile |

| Max. diamètre de forage |

Φ70 mm |

| Épaisseur maximale |

≤ 180 mm |

| Diamètre du robinet |

M3-M24 mm |

| Vitesse du fuseau |

30 à 3000 tours/min |

| Puissance du moteur de servo-fuseau |

22 kW |

| Distance de l'extrémité inférieure de la broche à la table de travail |

200 à 800 mm |

|

Mouvement latéral de la tête de puissance (axe X)

|

Max.course horizontale |

Unité de mesure |

| Vitesse de déplacement latéral |

0 à 9 tours/min |

| Servo-moteur pour mouvement latéral |

1x2,4 kW |

|

Mouvement longitudinal du gantry (axe Y)

|

Max. course d'alimentation |

4 000 mm |

| Vitesse de déplacement des aliments |

0 à 9 m/min |

| Puissance du servomoteur d'alimentation |

2x4,2 kW |

| Mouvement vertical de l'alimentation du bélier (axe Z) |

Max. coup de cœur |

600 mm |

| Vitesse de déplacement |

0 à 9 m/min |

| Servo moteur |

1x2,4 kW |

| Précision de positionnement à trois axes |

Le nombre d'équipements utilisés est déterminé en fonction de l'échantillon. |

± 0,015/1000 mm |

| Précision de positionnement répétée sur trois axes |

Le nombre d'équipements utilisés est déterminé en fonction de l'échantillon. |

± 0,01/1000 mm |

| Taille globale |

LxWxH |

6 000 x 3900 x 2700 mm |

Structure de la coulée par fractionnement:

Cet équipement CNC de forage et de fraisage de la bride de portique est principalement composé d'une table de travail à lit, de portique mobile, de selle mobile, de tête de puissance de forage et de fraisage, d'un système de lubrification automatique,mécanisme de protection, système de refroidissement en circulation, système de commande numérique et système électrique, entre autres composants clés.la machine-outil présente une précision de positionnement exceptionnelle et une précision de positionnement répétée.

Caractéristiques du produit

1. Tête de puissance de forage:

La tête de puissance de forage est équipée d'un moteur servo-fuseau dédié, qui entraîne une fuseau de précision spécialisée via une décélération de courroie synchrone dentée pour améliorer le couple de sortie.Il prend en charge le remplacement rapide et pratique, avec mouvement d'alimentation alimenté par un servo-moteur et un ensemble de vis à billes.permettant des fonctions d'interpolation linéaire et circulaireL'extrémité de la broche est conçue avec un trou conique BT40 et équipée d'un joint rotatif à grande vitesse, facilitant les opérations d'usinage du liquide de refroidissement à travers le centre de la perceuse U à grande vitesse.

2Système de transmission:

Le système adopte des guides et des curseurs taïwanais importés de haute précision, garantissant un fonctionnement en douceur tout en améliorant efficacement la capacité de charge lourde.

L'axe X et l'axe Z utilisent chacun deux voies de guidage linéaires roulantes comme rails de guidage et de support pour les mouvements horizontaux et verticaux, respectivement,qui répondent pleinement aux exigences techniques du forage à grande vitesseLa transmission de l'axe X et de l'axe Z est réalisée grâce à des servo-motors CA entraînant la rotation de vis à billes de précision, permettant un mouvement linéaire précis.

L'axe Y est équipé de deux voies de guidage linéaires roulantes lourdes sur les deux côtés, dont l'une dispose d'une structure montée sur le côté, formant ensemble la voie coulissante de l'axe Y.Cette configuration satisfait aux exigences de rigidité et de résistance élevées du cadre du portique, tout en offrant des avantages techniques tels qu'un faible coefficient de frottement, une vitesse de mouvement élevée, d'excellentes performances d'absorption des vibrations et une durée de vie prolongée.La transmission à axe X utilise une technologie d'entraînement synchrone à double servo-moteur, avec un servo-moteur installé de chaque côté, entraînant de manière synchrone la rotation des vis à billes., qui à son tour conduit le cadre du portique à se déplacer et permet des opérations d'usinage CNC.

.

.

Cette machine industrielle à portique CNC haute performance est dédiée aux opérations de forage et de marquage pour les composants de tôles et de tôles.Il est conçu de manière élaborée pour fournir un usinage de précision de pièces de travail de type plaque et de pièces structurelles, avec une adaptabilité ciblée à la transformation de brides, disques, anneaux, plaques plates et composants comparables.Une condition essentielle est que l'épaisseur de la pièce soit strictement conforme aux paramètres d'usinage efficaces préconfigurés de la machine.

Dans les usines de fabrication de structures en acier, cet équipement effectue des forages et des fraisages de précision sur les plaques structurelles et les composants de connexion,établissant une base solide pour l'assemblage stable des cadres en acierDans le secteur de l'énergie éolienne,Il fournit des solutions d'usinage de haute précision pour les tours et les brides des éoliennes, un processus essentiel qui garantit que ces composants peuvent résister à des conditions environnementales sévères (ePour les projets de construction de ponts, l'équipement traite les poutres de ponts et les supports, facilitant la formation de poutres stables,des connexions durables conçues pour supporter des charges dynamiques tout au long de la durée de vie prolongée du pont.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!