Taille de la pièce à usiner en feuille de métal à commande numérique 80 mm Maximum de diamètre de forage

Application du projet:

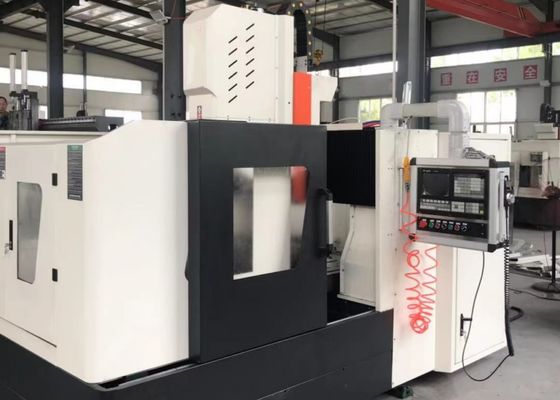

Cet équipement est principalement conçu pour effectuer des opérations de forage, de camérisation, de tapotement, de fraisage et de forage sur plaque et composants structurels.Il offre des performances de forage efficaces pour les pièces de travail, y compris les brides, disques, anneaux et plaques dont l'épaisseur se situe dans sa plage de fonctionnement effective, pouvant être traités à travers des trous ou des trous morts,il est compatible à la fois avec des composants mono-matériels et des matériaux compositesLa machine-outil est dotée d'un contrôle numérique de ses processus d'usinage, assurant une commodité opérationnelle exceptionnelle.et des capacités de production à grande échelle.

Les spécifications:

| Taille de la pièce |

LxW |

Pour les appareils à moteur: |

| Hauteur du gantry |

800 mm

(Il peut également être déterminé en fonction de la fondation)

|

| Tableau de travail |

Largeur de la fente en T |

28 mm |

| Tête de puissance de forage |

Je suis désolée. |

1 |

| Tone de la broche |

NT1 société civile |

|

Max. diamètre de forage

(acier au carbone ordinaire)

|

Φ80 mm |

| Épaisseur maximale |

≤ 150 mm |

| Diamètre du robinet |

M3 à M32 |

| Vitesse du fuseau |

30 à 3000 tours/min |

| Puissance du moteur de servo-fuseau |

22 kW |

| Distance de l'extrémité inférieure de la broche à la table de travail |

200 à 800 mm |

|

Mouvement latéral de la tête de puissance(axe X)

|

Max.course horizontale |

4 000 mm |

| Vitesse de déplacement latéral |

0 à 6 tours/min |

| Servo-moteur pour mouvement latéral |

4.2 kW |

|

Mouvement longitudinal du gantry (axe Y)

|

Max. course d'alimentation |

4 000 mm |

| Vitesse de déplacement des aliments |

0 à 6 m/min |

| Puissance du servomoteur d'alimentation |

2x4,2 kW |

| Mouvement vertical de l'alimentation du bélier (axe Z) |

Max. coup de cœur |

500 mm |

| Vitesse de déplacement |

0 à 6 m/min |

| Servo moteur |

3.5 kW (frénésie) |

| Précision de positionnement à trois axes |

Le nombre d'équipements utilisés est déterminé en fonction de l'échantillon. |

± 0,025/1000 mm |

| Précision de positionnement répétée sur trois axes |

Le nombre d'équipements utilisés est déterminé en fonction de l'échantillon. |

± 0,02/1000 mm |

| Taille globale |

LxWxH |

Pour les pièces de rechange |

| Puissance totale |

Environ 50 kW |

Structure de l'équipement

Cet équipement est principalement constitué d'un banc de travail en lit coulé, d'un portique mobile, d'une selle mobile, d'une tête de puissance de forage et de fraisage, d'un système de lubrification et de protection automatique,une unité de refroidissement en circulation, un système de commande numérique et un système électrique.tandis que les entraînements à vis à billes de précision garantissent une précision de positionnement supérieure et une excellente répétabilité.

Caractéristiques du produit

1- Lit et table de travail:

Le lit et la table de travail sont fabriqués en fonte grise (HT250) en pièces moulées, soumises à des traitements de recuit secondaire et de vieillissement,suivie d'une usinage de précision pour assurer une rigidité dynamique et statique exceptionnelle sans déformationLa surface de la table de travail est équipée de fentes en T usinées de précision dans une disposition optimisée, ce qui facilite le serrage sûr de la pièce.La base du lit est équipée de deux guides linéaires de haute précision de chaque côté, ce qui assure une répartition uniforme de la force sur les chariots de guidage et améliore considérablement la rigidité de la machine-outil ainsi que sa résistance à la traction et à la compression.Le système d'entraînement adopte des servo-moteurs AC couplés à des ensembles de vis à billes de précision pour l'entraînement bilatéralLes boulons de nivellement réglables sont placés stratégiquement sur la base du lit,permettant un étalonnage pratique de l'alignement horizontal du lit et de la table de travail.

2Le portail mobile:

Le portique mobile est construit en fonte grise (HT250), avec deux guides linéaires roulants à charge extrêmement élevée montés sur son côté avant.d'une puissance de sortie inférieure ou égale à 50 WLes têtes de puissance de forage sont fixées sur la glissière de la tête de puissance pour l'exécution opérationnelle.

3- Une selle en mouvement.

La selle mobile est un composant structural en fer moulé de précision, conçu pour une rigidité optimale et une stabilité opérationnelle.un ensemble d'assemblages de vis à billes de précision, et un réducteur planétaire de vitesse de haute précision couplé à un servo-moteur CA. Une bouteille de contre-balancement de gaz d'azote est intégrée dans la conception,compensation du poids de la tête de puissance pour minimiser la charge sur la vis à bille et prolonger sa durée de vieL'assemblage entraîne la tête de puissance de forage pour exécuter le mouvement de l'axe Z, permettant des fonctions de base, y compris la traverse rapide, l'alimentation de travail, la rétraction rapide et l'arrêt de positionnement précis.Il est également équipé d'une cassure automatique des puces, l'évacuation des puces et les capacités de pause de programme pour améliorer l'efficacité de l'usinage et le contrôle des processus.

.

.

Cette machine industrielle à portique CNC haute performance est dédiée aux opérations de forage et de marquage pour les composants de tôles et de tôles.Il est méticuleusement conçu pour fournir l'usinage de précision des pièces de travail de type plaque et des pièces structurelles, avec une adaptabilité spécialisée au traitement des brides, disques, anneaux, plaques plates et composants analogues.Une exigence fondamentale est que l'épaisseur de la pièce doit être strictement conforme aux paramètres d'usinage efficaces prédéfinis de la machine.

Dans les installations de fabrication de structures en acier, cet équipement effectue des forages et des fraisages de précision sur les plaques structurelles et les composants de connexion,établissant une base solide pour l'assemblage stable des cadres en acierDans le secteur de l'énergie éolienne,Il fournit des solutions d'usinage de haute précision pour les tours et les brides d'éoliennes, un processus essentiel qui garantit que ces composants peuvent résister à des conditions environnementales extrêmes (ePour les projets de construction de ponts, l'équipement traite les poutres de ponts et les supports, permettant la formation de poutres stables, de poutres de support et de poutres de support.des connexions durables conçues pour supporter des charges dynamiques pendant toute la durée de vie prolongée du pont.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!